- There are no more items in your cart

- Shipping

- Total 0.00 zł

- Bestsellers

- Wholesale

- Water filters

- Whole house filters

- Kitchen filters

- Bathroom filters

- Aquarium filters

- Reverse osmosis

- Water demineralizers

- Filter cartridges

- UV bactericidal lamps

- Alkaline water ionizers

- Industrial water filters

- Accessories, parts, and others

- Descaling filters for the coffee machine

- Water softeners and iron removers

- Water saturators

- ACES

- AMBERLITE

- AQUA VITA

- AQUAFILTER

- AQUAPHOR

- AQUATOR

- BASSAU

- BERG

- BIOCERA

- BIONIQ

- BLUEFILTERS

- CHEMOFORM

- CINTROPUR

- DAFI

- DELONGHI

- DIAMOND

- DOM WODY

- ECOWATER

- FILMTEC

- FIT ALCO

- FITAQUA

- GREEN FILTER

- HANNA INSTRUMENTS

- HELIXPRO

- HELLO PURE

- HIDROTEK

- HM-DIGITAL

- HONEYWELL

- Ibo

- JAVEL

- KLARWOD

- KRUPS

- MIDEA

- OTOWODA

- OTTONE

- Palintest

- PENTAIR

- PHILIPS

- PLATINUM WASSER

- PUROLITE

- SIEMENS

- Steingraf

- SUPREME

- TAB-SOL

- TOP FILTER

- UST-M

- USTM

- VONTRON

- WODARO

Tips

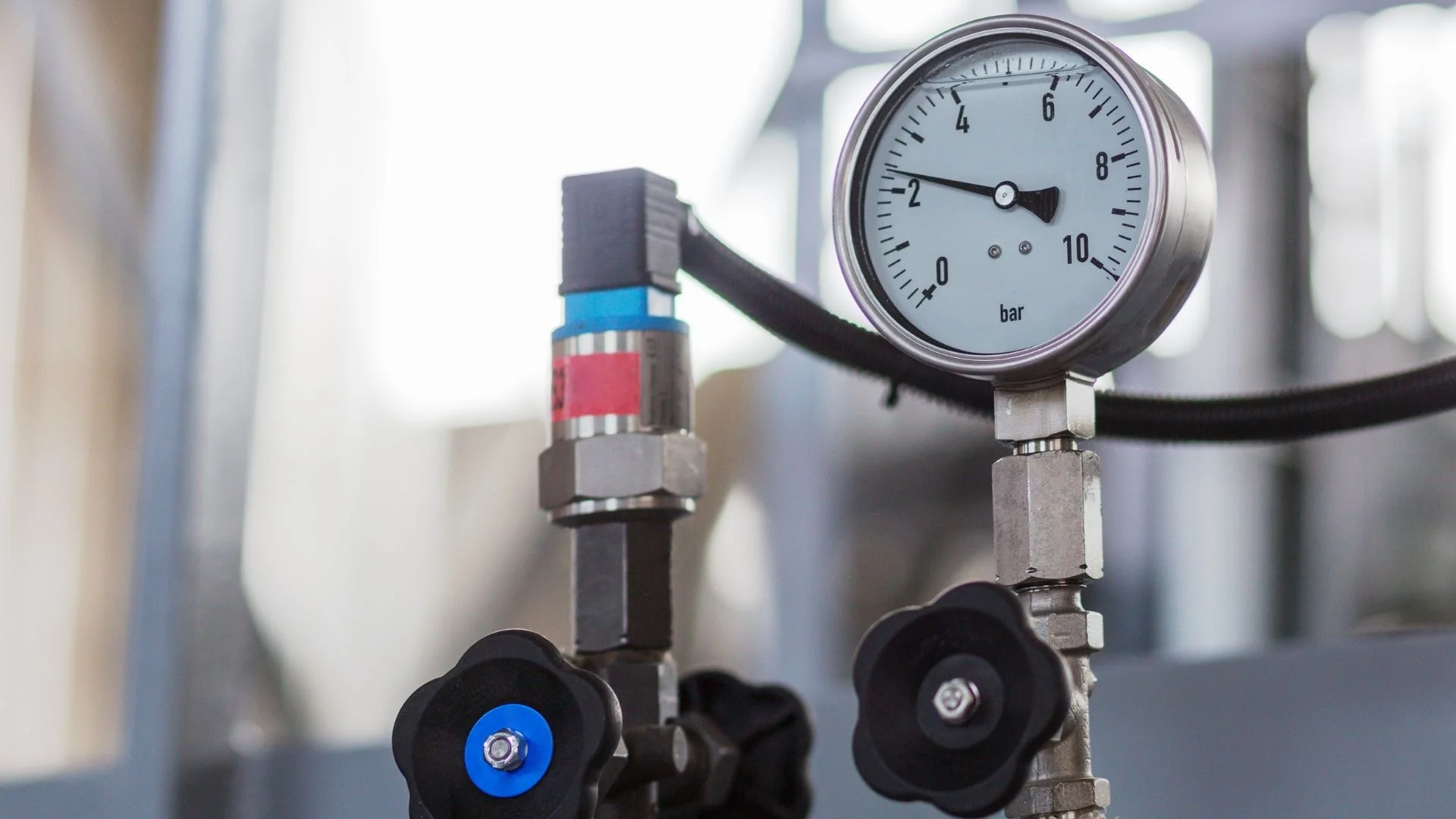

Manometers and Water Pressure Gauges for Measuring Pressure

If you want to ensure that your water system maintains the appropriate water pressure, manometers and pressure gauges are essential devices that should be included in every water network. Whether you want to monitor water flow in your home plumbing system or have more specialized needs, properly selected manometers can help avoid problems related to clogged pipes, weak water flow, or damage to the water system. In our store, you will find a wide selection of these devices that will meet all your technical requirements.

Filter

Price

Brand

Brass manometer pressure gauge 1/4 10 bar

What is a manometer and how does it work?

A manometer is a precise measuring device used to determine the pressure of fluids and gases in closed systems. In a home plumbing installation, manometers are extremely useful for monitoring the appropriate water pressure, which is crucial for maintaining system efficiency and preventing potential problems such as clogged pipes or weak water flow.

The principle of operation of a manometer is based on measuring the pressure difference between the substance being tested and atmospheric pressure. The most popular types of manometers, such as mechanical manometers, use flexible elements like diaphragms or Bourdon tubes that deform under pressure. This deformation is converted into the movement of the pointer on the manometer dial, allowing for an accurate reading of the pressure value.

Types of manometers and pressure gauges

The variety of manometers available on the market allows them to be tailored to the specific needs of users. They differ not only in design but also in purpose and measurement accuracy. The choice of the appropriate model depends on their diameter, type of connection, and the specifics of the application for which they are intended.

Bottom connection manometers (bottom manometers)

Bottom manometers are a classic choice for installation on vertical pipes or in places where pressure readings are easily accessible at eye level. They are often used in industry and in home installations where constant pressure monitoring is necessary.

Back connection manometers (rear manometers)

Back manometers feature a connection located at the back of the device, allowing for installation on control panels or dashboards. Ideal for applications where it is necessary to integrate the manometer into a housing or cabinet, improving the aesthetics of the installation.

Panel manometers (for mounting in a housing)

These manometers are designed for installation in panels or control boards, where reading the pressure value is crucial for machine operators. They offer an aesthetic and functional solution, allowing easy access to readings.

Manometers with 1/4 and 1/2 inch threads

The threads in manometers are an important aspect to consider when choosing them. Standard 1/4 and 1/2 inch threads are the most commonly encountered, making them easier to install in various systems. The choice of the appropriate thread depends on the specifics of the installation to which the manometer is to be connected.

Manometers with a diameter of 63 mm and 100 mm

The diameter of the manometer dial is significant in terms of readability. Standard manometers with a diameter of 63 mm are sufficient for most home and industrial applications, while larger dials, such as 100 mm, are preferred in places where precise readings from a greater distance are required.

Vacuum gauges (measuring vacuum)

Vacuum gauges, specializing in measuring vacuum, are essential in installations where the pressure is lower than atmospheric. Used in vacuum applications and ventilation systems, they provide precise measurements, crucial for many technological processes.

Chemical manometers

Chemical manometers are specially designed to work with aggressive media that can damage standard measuring devices. Made from corrosion-resistant materials such as stainless steel or plastics, they are essential in the chemical and pharmaceutical industries.

Contact manometers

Contact manometers, equipped with additional electrical contacts, can be used for automatic process control. They enable monitoring and control of pressure in systems, which is crucial in applications requiring precise regulation.

Manometers with a pressure range from -1 to 1000 bar

The pressure range is one of the most important parameters when choosing a manometer. Models with a wide range from -1 to 1000 bar are versatile and can be used in many applications, from low to very high pressures.

Manometers with dial diameters from Ø40 to Ø160

The choice of the appropriate dial diameter depends on the installation location and reading requirements. Manometers with smaller dials (Ø40 mm) are compact and ideal for applications where space is limited, while larger dials (Ø160 mm) offer better readability.

Capsule manometers

Capsule manometers are special devices for measuring low pressures and pressure differences. They use a capsule design for accurate pressure measurement, making them ideal for monitoring sensitive systems such as HVAC.

Stainless steel manometers

Stainless steel is a material chosen for its corrosion resistance and durability. Manometers made from this material are robust and ideal for use in harsh conditions where contact with water, chemicals, or other aggressive substances is unavoidable.

Manometers for measuring pressure differences

Differential manometers are specially designed to measure the pressure difference between two points. They are essential in ventilation, filtration, and hydraulic systems where flow control is crucial.

Contact manometers

Contact manometers, in addition to standard measuring functions, can trigger alarms or activate devices in response to pressure changes. They are used in advanced control systems where process automation is a priority.

Precision manometers (for very precise measurements)

When very accurate measurements are required, precision manometers are indispensable. They offer high accuracy and are used in laboratories, industry, and medical applications where even the smallest pressure deviations matter.

Glycerin-filled stainless steel manometers

Filled with glycerin, these manometers offer better reading stability and protection against vibrations. Ideal for use in harsh conditions where vibrations may affect measurement accuracy, and glycerin acts as a damper.

Heating manometers

Specifically designed for heating systems, these manometers allow for monitoring pressure in central heating systems. They make it easy to control and maintain optimal operating conditions for heating installations.

Diaphragm manometers

Diaphragm manometers are ideal for measuring pressures in systems where the medium may be viscous or contain solid particles. With a diaphragm protecting the measuring mechanism, they are resistant to contamination and prevent device blockage.

How to install a manometer?

Installing a manometer is a crucial step that affects the accuracy and durability of the device. Here are a few steps to consider:

-

Choosing the right location - The manometer should be installed in a place where it is easily accessible for reading, but at the same time protected from mechanical damage.

-

Protection against vibrations - In systems exposed to vibrations, manometers should be equipped with dampers or mounted on special brackets.

-

Using the proper sealing - During installation, appropriate seals should be used, such as PTFE tape, to prevent leaks.

Accuracy classes of pressure gauges

The accuracy of measurement is one of the key parameters of a manometer, determining how precisely the device measures pressure. Accuracy classes are usually marked on the manometer dial and can range from 0.1% to 4%. The choice of accuracy class depends on the application requirements - higher accuracy is essential in precise technological processes, while lower accuracy is sufficient for everyday household applications.

Scales in pressure gauges

The scale on the manometer dial determines the accuracy of the reading. Common scales include 0.1, 0.5, 1, 2 bar, meaning that the smallest value that can be read is 0.1, 0.5, 1, or 2 bar, respectively. Choosing the appropriate scale is important to obtain an accurate and readable reading within a given pressure range.

Water pressure gauges and manometers at mojawoda.com

At the mojawoda.com store, you will find a wide selection of pressure gauges and manometers tailored for various applications, from standard household models to manometers for reverse osmosis and specialized industrial pressure gauges.

We offer high-quality products that will help you maintain optimal water pressure in installations and ensure lower water consumption and protection of the system against damage.

Applications of manometers and pressure gauges

Manometers are widely used in various fields, both in industry and in households. They are essential for monitoring pressure in water treatment filters, hydraulic, pneumatic, heating, and ventilation systems. In a domestic water supply installation, manometers help control water pressure, which is crucial for protecting devices and ensuring user comfort.

What is the water pressure in a house?

Optimal water pressure in a house is a matter of not only convenience but also safety of the installation. The correct water pressure in a house should be between 2 to 4 bar. Too low or too high pressure can lead to problems such as weak water flow or damage to the installation. Therefore, it is important to regularly check the water pressure at the tap and adjust it to individual needs.

Too low water pressure - how to increase water pressure?

If you notice a drop in water pressure in the installation, it may be caused by various factors such as low water pressure in the network, clogged pipes, or a pump failure. To raise the water pressure, you can apply several methods:

-

Check and clean filters - Often, the cause of low pressure is a clogged filter that restricts water flow.

-

Adjust the pressure reducing valve - In some cases, it is necessary to adjust the pressure reducing valve, which may be set to too low a pressure.

-

Use pressure-boosting pumps - In places where water pressure is consistently too low, it is worth considering the installation of booster pumps.

Too high water pressure in the installation

Increased water pressure in the installation can lead to damage to pipes and devices. Higher pressure may be caused by an error in the pressure regulator settings or by an increase in pressure in the water supply network. To limit water flow and protect the installation, it is advisable to install pressure reducers, pressure reducing valves, or diaphragm expansion tanks that absorb excess pressure.

Summary of manometers for measuring water pressure

Manometers are an essential element of any water installation, ensuring control over the appropriate water pressure. Regular monitoring of pressure and periodic cleaning of pipes are key actions that help maintain the installation in excellent condition and prevent problems related to improper pressure. With a wide selection of manometers in our store, you can find the right model tailored to your needs, ensuring comfort and safety in using the water system.

Author: Maciej Waliduda