- There are no more items in your cart

- Shipping

- Total 0.00 zł

- Bestsellers

- Wholesale

- Water filters

- Whole house filters

- Kitchen filters

- Bathroom filters

- Aquarium filters

- Reverse osmosis

- Water demineralizers

- Filter cartridges

- UV bactericidal lamps

- Alkaline water ionizers

- Industrial water filters

- Accessories, parts, and others

- Descaling filters for the coffee machine

- Water softeners and iron removers

- Water saturators

- ACES

- AMBERLITE

- AQUA VITA

- AQUAFILTER

- AQUAPHOR

- AQUATOR

- BASSAU

- BERG

- BIOCERA

- BIONIQ

- BLUEFILTERS

- CHEMOFORM

- CINTROPUR

- DAFI

- DELONGHI

- DIAMOND

- DOM WODY

- ECOWATER

- FILMTEC

- FIT ALCO

- FITAQUA

- GREEN FILTER

- HANNA INSTRUMENTS

- HELIXPRO

- HELLO PURE

- HIDROTEK

- HM-DIGITAL

- HONEYWELL

- Ibo

- JAVEL

- KLARWOD

- KRUPS

- MIDEA

- OTOWODA

- OTTONE

- Palintest

- PENTAIR

- PHILIPS

- PLATINUM WASSER

- PUROLITE

- SIEMENS

- Steingraf

- SUPREME

- TAB-SOL

- TOP FILTER

- UST-M

- USTM

- VONTRON

- WODARO

Tips

Water Pumps

Water pumps are devices that play a crucial role in various water systems. They can be found in both simple home installations and more advanced industrial and agricultural solutions. They are essential for transporting water from one place to another, enabling activities such as irrigation, water supply, and effective purification.

Filter

Price

Brand

What is a water pump?

A water pump is a mechanical device used to transfer water from one place to another using mechanical energy. The main component of the pump is the motor, which drives the impeller or piston, causing water to flow through the system. The power of the motor, expressed in watts (W) or horsepower (HP), determines the efficiency of the device, that is, the amount of water the pump can move in a unit of time and the pressure it can generate.

Connecting hoses, often referred to as pipes or tubes, play a crucial role in the water pump system. They are used to connect the equipment to the water source and the delivery point, enabling efficient water transfer. Hoses can be made from various materials, including rubber, plastics, or metal, depending on the model specifications and its application. They allow for easy connection and disconnection of the pump, which is particularly important in portable systems and installations that require regular maintenance.

Types of water pumps

Centrifugal pumps

Centrifugal pumps are the most commonly used type of water pumps. They operate on the principle of centrifugal force generated by an impeller rotating within the pump casing. The liquid enters the center of the impeller and is expelled outward due to centrifugal forces, causing water to flow through the system. Centrifugal pumps have a wide range of applications, such as: supplying drinking water, irrigation systems, or industrial cooling systems.

Piston pumps

A piston pump is a type of suction pump that operates based on the movement of a piston within a cylinder. This action causes the suction and expulsion of water. Piston pumps are used in situations requiring high pressure, such as powering steam boilers, high-pressure systems, and some irrigation systems. They are characterized by high efficiency and durability, but are more complex and require regular maintenance.

Submersible pumps

Submersible pumps, as the name suggests, are designed to operate fully submerged in water. They are often used in deep wells, drainage systems, fountains, and sewage systems. These pumps can be centrifugal or positive displacement and are valued for their reliability and ability to work in challenging conditions.

Jet pumps

Jet pumps use a high-speed water jet to draw in and transport liquids. They are mainly used in situations where it is necessary to lift water to a great height, for example, in water supply systems in multi-story buildings or in agricultural irrigation systems. Jet pumps are less efficient than centrifugal pumps, although they may perform better than them in specific conditions.

Operating principles of clean and dirty water pumps

Operating principle of centrifugal pumps

Centrifugal pumps operate thanks to an impeller that rotates inside the pump casing. This impeller has blades that move water from the center to the outside, increasing its speed and kinetic energy. This kinetic energy is then converted into pressure energy as the water leaves the impeller and enters the diffuser or spiral casing, which directs it to the pump outlet. Thanks to this principle, centrifugal pumps can process large amounts of water at relatively low pressure.

Operating principle of piston pumps

Piston pumps operate on the principle of moving a piston within a cylinder, which causes the suction and expulsion of water. The piston moves up and down or back and forth, creating a vacuum that draws water into the cylinder and then expels it through the outlet valve as the piston retracts. This operation of the piston pump allows it to generate very high pressure, making it ideal for applications requiring significant force.

Operating principle of submersible pumps

Submersible pumps operate similarly to centrifugal pumps. So what is the difference in their operation? As already known, a submersible pump is designed to work fully submerged in water. The pump motor is hermetically sealed, preventing any moisture from entering the interior. The pump's impeller draws water through openings in the casing and moves it outward, creating flow. Submersible pumps are particularly useful in situations where it is necessary to lift water from great depths, such as in deep wells.

Applications of water pumps

Supply of drinking water

One of the most important applications of water pumps is the supply of drinking water. Pumps are used to transport water from water sources such as wells, rivers, or lakes to water supply systems, where it is purified and distributed to homes and businesses. Centrifugal and piston pumps are particularly popular in this context due to their high efficiency and reliability.

Irrigation systems

Water pumps are essential in irrigation systems that provide water to plants in agriculture, horticulture, and fruit growing. These devices are used to transport water from water sources to irrigation systems, such as sprinklers, drip irrigation systems, or irrigation ditches. Jet and submersible pumps are often used for these activities due to their ability to lift water to great heights and operate in challenging conditions.

Industrial cooling systems

In industry, water pumps are crucial for cooling systems that remove excess heat from technological processes. Water is used as a cooling medium that absorbs heat and transports it away from equipment and machines. Centrifugal pumps are often used in these systems due to their ability to process large amounts of water at relatively low pressure.

Sewage systems and wastewater treatment plants

Water pumps are also essential in sewage systems and wastewater treatment plants. They are used to transport sewage from homes and businesses to treatment plants, where it is then subjected to purification processes. Submersible pumps are particularly useful for these activities due to their ability to operate in challenging conditions and process contaminated water.

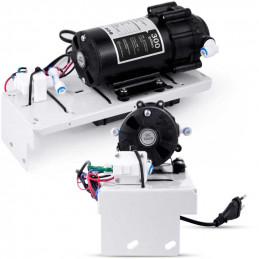

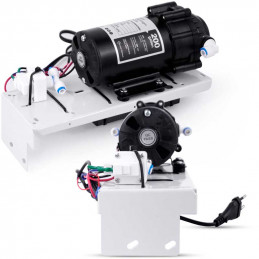

Electric water pumps for reverse osmosis

In our store, we offer highly efficient electric pumps dedicated to reverse osmosis systems. Why is such a pump the best solution for RO filters? The answer can be found below.

Operating principle of reverse osmosis systems

Reverse osmosis (RO) is a water filtration process that removes contaminants from water by passing it through a semi-permeable membrane. Water under high pressure is pushed through the membrane, which retains contaminants such as salts, bacteria, viruses, and chemicals, allowing only pure water molecules to pass through. As a result of this process, high-purity water is obtained, which is safe for both consumption and other applications.

The Role of Water Pumps in RO Systems

An electric pump is equipment that provides invaluable support for the reverse osmosis filter, ensuring the necessary pressure to push water through the membrane. These devices are designed to operate at high pressure, which is essential for effectively removing contaminants from water. Various types of pumps are used in RO systems, including centrifugal and piston pumps, depending on specific requirements.

Performance and Reliability of Pumps in Reverse Osmosis Systems

Electric water pumps used in reverse osmosis systems must be efficient and reliable to ensure a continuous and effective filtration process. High-quality models are designed to withstand prolonged loads and operate in harsh conditions, such as high water hardness or the presence of multiple contaminants. Regular maintenance and servicing of pumps are crucial for maintaining their performance and longevity.

FAQ – Frequently Asked Questions

1. What is a water pump and how does it work?

A water pump is a mechanical device used to transfer water from one place to another using mechanical energy. The pump's motor drives a rotor or piston, causing water to flow through the system. The motor's power determines the pump's efficiency, which is the amount of water the equipment can move in a unit of time and the pressure it can generate.

2. What are the main types of water pumps?

The main types of water pumps are:

-

Centrifugal Pumps – operate on the principle of centrifugal force generated by the rotor.

-

Piston Pumps – operate on the principle of moving a piston within a cylinder.

-

Submersible Pumps – designed to operate fully submerged in water.

-

Jet Pumps – use a high-speed water jet to draw in and transport liquids.

3. What are the applications of water pumps?

Water pumps are used in various fields, including:

-

Drinking Water Supply – transport water from water sources to plumbing systems.

-

Irrigation Systems – provide water to plants in agriculture, horticulture, and orcharding.

-

Industrial Cooling Systems – remove excess heat from industrial processes.

-

Sewage Systems and Wastewater Treatment Plants – transport sewage to treatment facilities.

4. What are connection hoses and what is their role?

Connection hoses, also known as pipes or tubes, are used to connect the pump to the water source and the delivery point. They enable efficient water transfer and are made from various materials such as rubber, plastics, or metal. They allow for easy connection and disconnection of the pump, which is important in portable solutions and installations requiring regular servicing.

5. What is the significance of water pumps in reverse osmosis (RO) systems?

Electric water pumps are extremely important for reverse osmosis systems as they provide the necessary pressure to push water through the semi-permeable membrane. These devices must be efficient and reliable to ensure a continuous and effective filtration process, removing contaminants from water and delivering high-quality pure water. Regular maintenance of pumps is crucial for maintaining their high performance over time.